Equipment

- Home

- Equipment

Our Equipment

At Electrical Daddy Pvt Ltd, we leverage advanced tools and technologies to deliver precise and reliable electrical engineering services. Our state-of-the-art equipment ensures efficient testing, commissioning, and maintenance of various electrical systems, meeting the highest industry standards.

Explore our cutting-edge equipment that powers our expertise:

Tan Delta (Omicron)

Ensures accurate measurement of insulation condition in high-voltage equipment to prevent failures.

CT Analyzer (Omicron)

Performs precise testing and analysis of current transformers for optimal system performance.

Relay (Omicron)

Offers advanced relay testing capabilities to ensure system protection and reliability.

DCRM (Scope)

Tests dynamic contact resistance of circuit breakers, crucial for reliable operation.

Circuit Timing and CRM (Scope)

Enables detailed testing of circuit breaker timing and contact resistance.

Primary Injection up to 2500 A

Facilitates high-current testing for protection systems and switchgear.

Cable Fault Locator (Scope)

Accurately identifies and locates faults in power cables up to 132 KV class, minimizing downtime.

Thermography (Flir)

Thermal imaging technology detects potential issues in electrical systems before failures occur.

Turn Ratio (Scope & Veer Electronics)

Performs transformer turn ratio testing to ensure operational efficiency.

Wind Resistance 25 A (Scope)

Measures winding resistance to assess transformer and motor health.

Single Phase Relay Testing

Tests single-phase relays for enhanced protection system functionality.

DC High Pot up to 70 KV

Conducts DC high-voltage testing to ensure insulation integrity.

AC High Pot up to 50 KV

Performs AC high-voltage testing for dielectric strength assessment.

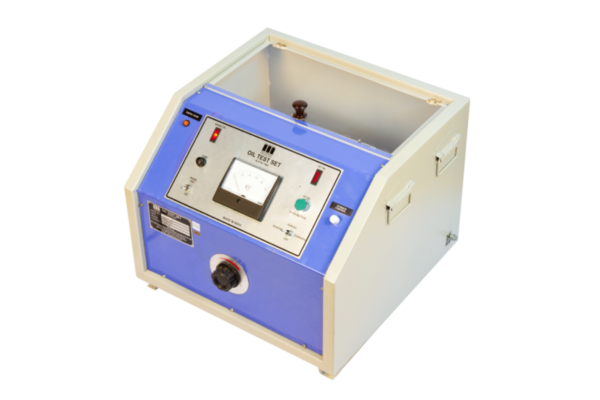

Oil Testing

Analyzes transformer oil quality to ensure equipment reliability and longevity.

Vibration Testing

Detects mechanical issues in motors and generators to prevent damage.

Partial Discharge Testing

Identifies partial discharges in high-voltage equipment to ensure insulation health.

Oil Filter Machine (3 KL, 6 KL, 12 KL)

Removes impurities from transformer oil, improving performance and lifespan.

Oil Storage Tank (10 KL)

Facilitates safe storage and handling of transformer oil for on-site applications.

Why Our Equipment Stands Out

Advanced Technology

We invest in the latest tools to deliver precision and efficiency.

Wide Range

Our extensive inventory covers diverse testing and commissioning requirements.

Quality Assurance

Our equipment ensures adherence to stringent industry standards.